At Cultivation Warehouse we work with hundreds of manufacturers and suppliers to find the optimal solutions to maximize crop performance and reduce the costs of production. With energy and labor accounting for the largest share of those costs it is imperative that growers pay close attention to how they can reduce their energy consumption and increase automation into their process.

The best way to maintain the quality and consistency required by the marketplace and to keep a lid on costs is to accurately monitor every phase of your operation.

There are a growing number of companies focusing on providing the digital tools to provide for . data driven farm management and automation solutions. Operating out of Denver, Colorado, Growlink™ has been a pioneer in this space, helping farmers deliver the perfect environment, the right amount of water and nutrients at the right time and collecting and using real time data to ensure predictable and profitable results.

CEO Ted Tanner shares many of our values including a focus on maximizing yield and minimizing operating costs.

According to Tanner, “We help farmers experience massive crop growth by using automated systems custom built with tightly integrated hardware and software to power the future of cultivation.

“Like Cultivation Warehouse we measure our success by the success of the farmer, which is why we value our partnership and enjoy working with the team at CW.

“In the past, if you wanted bigger harvests, you needed more space, more water, more fertilizer, and more labor. Growlink’s proprietary technology is optimizing the relationship between cost and output.”

Tanner founded Growlink with the help of associates, David Holmes, Stephen Ely, and Matt Roybal, in 2016. The team started by designing consumer-based hydroponic automated grow systems affectionately known as the Hydropods, The Hydropods soon transitioned to commercial hydroponic growing automation and evolved into Growlink.

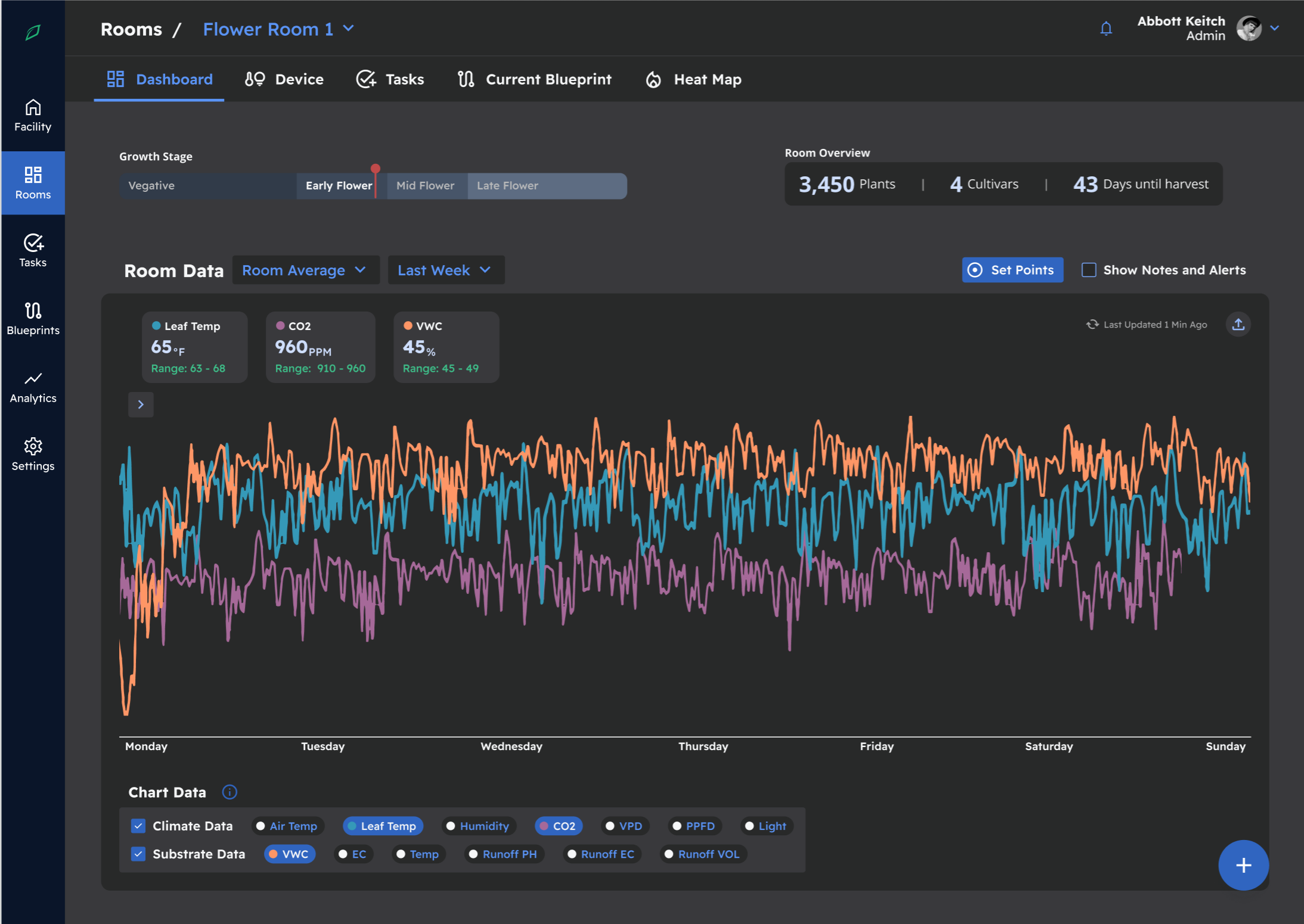

The vision continues to grow and under Ted’s leadership the company continues to innovate and expand their hardware and software product offerings to include sensors, controllers, and a powerful operating system that can connect all of the technology in your farm to work in unison. You and your team can control nearly every device and system in the farm in ways that are intuitive and easy to use.

This summer Growlink announced a new soilless substrate calibration, providing even more accurate VWC and EC data (pictured below).

In November Growlink will be showing off a new Capacitance substrate sensor and upgraded back end systems in anticipation of the roll-out of the Growlink 365 platform (pictured below).