To a large extent, sustainable Controlled Environment Agriculture (CEA) depends on the design of the cultivation facility. At Cultivation Warehouse we help our clients make successful moves to improve facilities and operations, including swapping lighting technologies, making greener choices about HVAC and power supplies, improving layouts for efficiency and reducing consumables. We also focus on design solutions that improve yield, quality, consistency, and plant health.

The use of racking systems to maximize available canopy area have long been a key component in the CEA industry, and we work with a number of manufacturers offering a variety of systems for both cannabis and food crops.

The type and placement of racking systems can create microclimates and drainage issues, both of which can result in reduced yield, crop inconsistency, and the diminished quality of finished plants.

Achieving consistent airflow within the canopy envelope is a critical design issue both to mitigate microclimates and ensure optimal under canopy air distribution. Traditional designs focused on over canopy airflow, either through oscillating fans mounted on the rack uprights or room walls.

Dual Draft Integrated Airflow was developed and patented by Integrated Hydro Solutions, a California product development firm, specifically to address these issues.

According to Cultivation Warehouse co-founder Eric Paulin, “Dual Draft checks all the boxes for improving airflow and drainage within the plant environment for single tier and vertical farms.

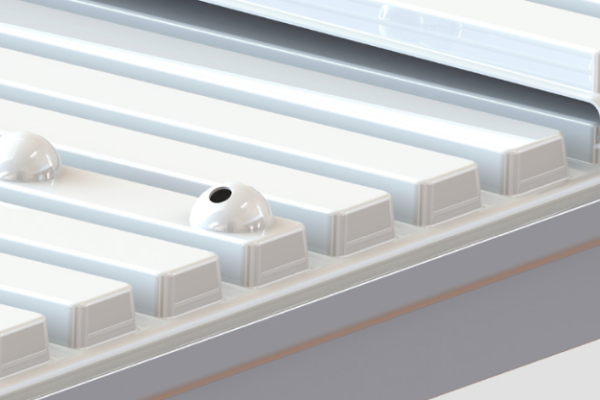

Their newest product, the Infinity Tray, uses a continuous gutter system that allows for one or multiple points of drainage with a patented design that ensures complete drainage after every irrigation event and it interlocks requiring no sealant or adhesive for easy installation.”

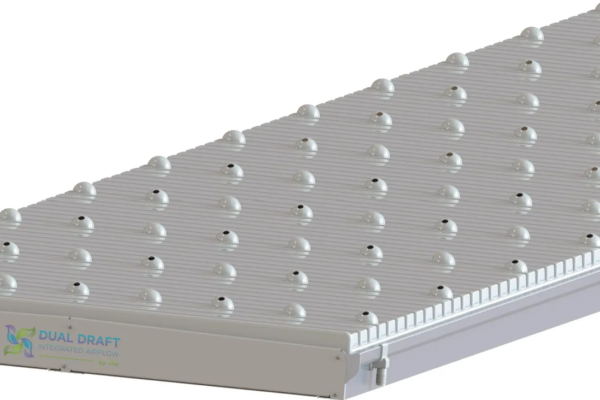

Dual Draft Infinity Tray

Dual Draft features a novel design that integrates an advanced airflow duct system directly into the plant tray. The system is designed to move air through the plant canopy from below, as well as move air down onto the plants from above.

The Dual Draft system can be installed on existing racks from all major manufacturers, or the system can be designed as part of a new project.

Specifically engineered to address the issues of microclimates and drainage found especially in vertical farming applications Dual Draft provides advantages particularly beneficial for growers focused on yield per square foot and quality with existing crop equipment and methodologies. For cultivators in highly competitive markets, Dual Draft is an economical solution to address increasing operational costs and decreasing pricing of finished goods.

Controlled Environment Agriculture facilities are really manufacturing plants, where consistency and predictability come from a homogenous environment

Leigh Zalusky, CTO and Founder of Integrated Hydro Solutions, said he was excited to collaborate with the team at Cultivation Warehouse. “Their expert design services ensure that every customer receives a facility that operates cost-effectively. Now, Cultivation Warehouse customers get the added benefit of an agnostic approach to equipment selection combined with Dual Draft’s ease of integration into all leading bench and racking providers.”