AUTOMATION IS THE FUTURE AND THE FUTURE IS NOW

Growing the most valuable product at the lowest possible cost should be the goal of every producer. The benefits of vertical farming are increasingly well known. Increasing the canopy size without increasing the physical footprint of your facility is a prime example of cost reductions available to indoor growers. Reducing labor costs through automation is another.

At CW, we pride ourselves on keeping up to date on the latest advances in ag technology, and from where we sit, it’s clear that automation is driving the latest wave of competitive growth in the cannabis space.

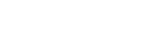

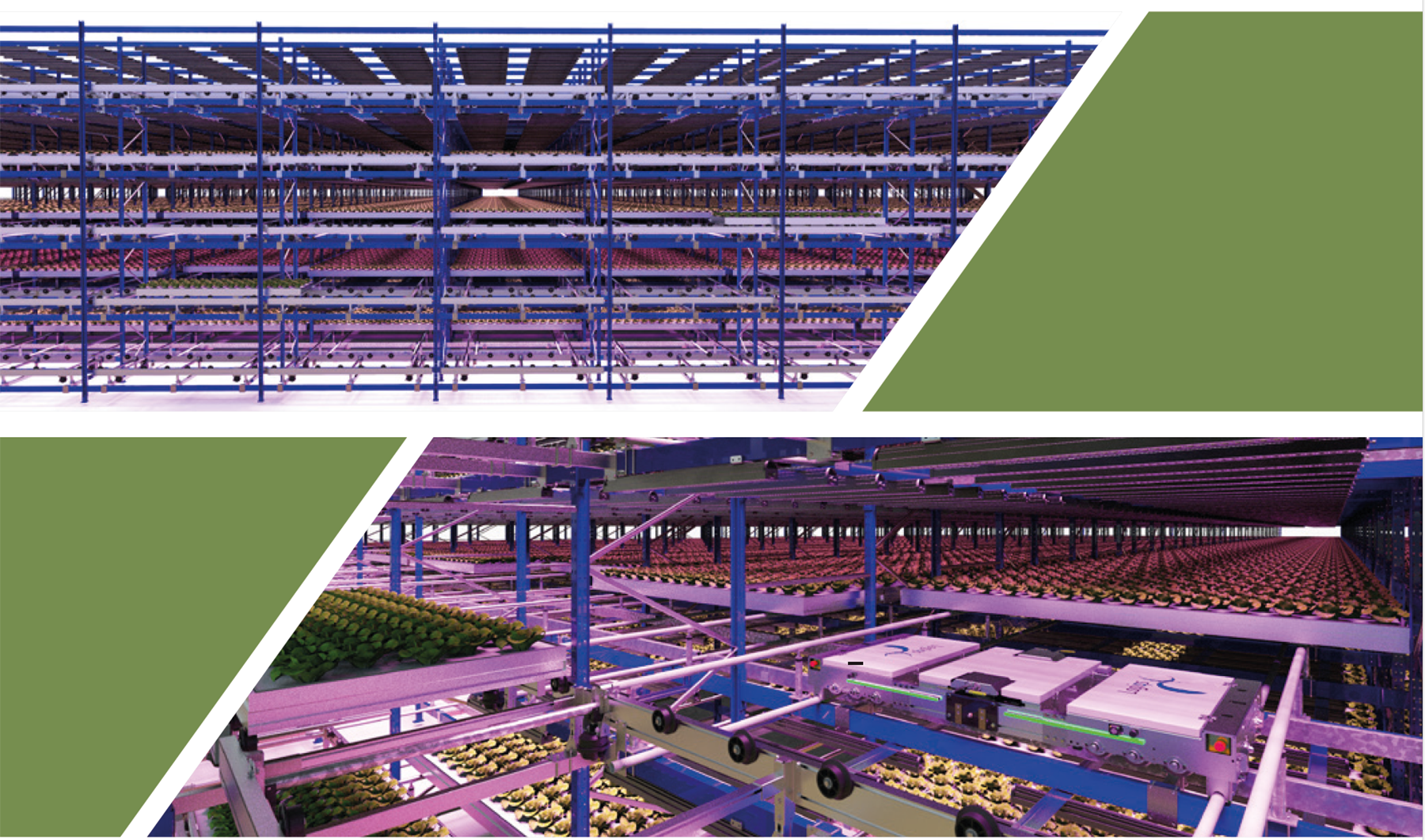

This month, we’re shining the automation spotlight on the new Green Cube by Hove. This vertical farming system increases canopy space using one simple tactic: reducing labor. In utilizing their 2D Shuttles (built by Loqiq) to automate movement of plant tables up, down, in and out of the Green Cube system, the need to allocate precious square footage for aisles and walkways becomes a thing of the past.

Additional benefits of decreasing the human footprint in cultivation rooms include:

- Less touch points for plant maintenance.

- Tighter controls on IPM and cross-contamination

- Freedom to schedule plant moving events during non-work hours.

Additionally, the Green Cube sets the stage to integrate even more supplementary automation equipment, including plant spacing and media loading systems.

To learn more about the Green Cube, visit www.hoveintl.com or contact your dedicated CW Cultivation Expert.