When growers consider or adopt LED lighting, there are various issues they need to address. You can find several of these concerns discussed in an article from last month.

There are a multitude of LED light companies and products available, making it challenging to choose the right option. Cultivation Warehouse can assist in comparing and selecting the appropriate LED lighting solution for your needs. One company that Cultivation Warehouse has enjoyed working with for an extended period is the Netherlands-based horticulture lighting company, Dutch Lighting Innovations (DLI).

DLI has a strong background in horticulture for food production, houseplants, and cut flowers. For over 25 years, they have been designing customized lighting recipes using the most suitable technology for their customers.

We interviewed Jair Velleman and Jerome Dercksen from DLI, who shared their insights on LED and UV lighting, particularly with regards to cannabis applications.

”LED use in horticulture is relatively new. The commercial application in grow lights has only come in the last decade. As with any new technology, it has taken some time to observe and discover the efficacy of LED lights and UV in particular on various plants and their growth cycle.

“The advances of adjustable full spectrum LED lamps allow cultivators new plant light recipes that can be tailor-made to their needs by adjusting light intensity, duration, wavelength (color), and illumination schedule.

“We do love Cannabis cultivation – we’ve been lighting cannabis grows for a while now.- and we’ve gained a lot of knowledge over the last decade that we’ve been applying to create specific fixtures for the best results.

“Did you know that using UV grow lights can greatly enhance the flavor and aroma of your plants? That’s right, it’s all thanks to the improvement of terpene production!

“Plants have evolved to the solar spectrum for millions of years so it should not come as a surprise that plants respond to the various types of wavelengths found in their natural environment. As we take plants indoors, we are in full control and we need to provide plants with everything they need.

“Most of the lights commonly used to grow plants only produce wavelengths within the visible light spectrum and infrared. With decades of experience growing plants indoors with these systems, it seems UV is not required for plant growth but is there a benefit?

“As UV photons are more energetic than visible light, they have different effects and can even produce damage. Out of the three types of UV, the most dangerous and powerful one, UV-C is filtered out by the atmosphere, so plants have not evolved to cope with them. UV-B is only present in lower amounts but UV-A is plentiful when the sun is out in full force.

“We know from experience that plants respond to UV and we’ve discovered specific photoreceptors that influence how plants grow and metabolize. It’s well known by now that UV can increase and or change the makeup of terpenes and other metabolites but there are many other benefits of UV. There is a clear health benefit to plants as leaf thickness can increase, lowering susceptibility to pests.

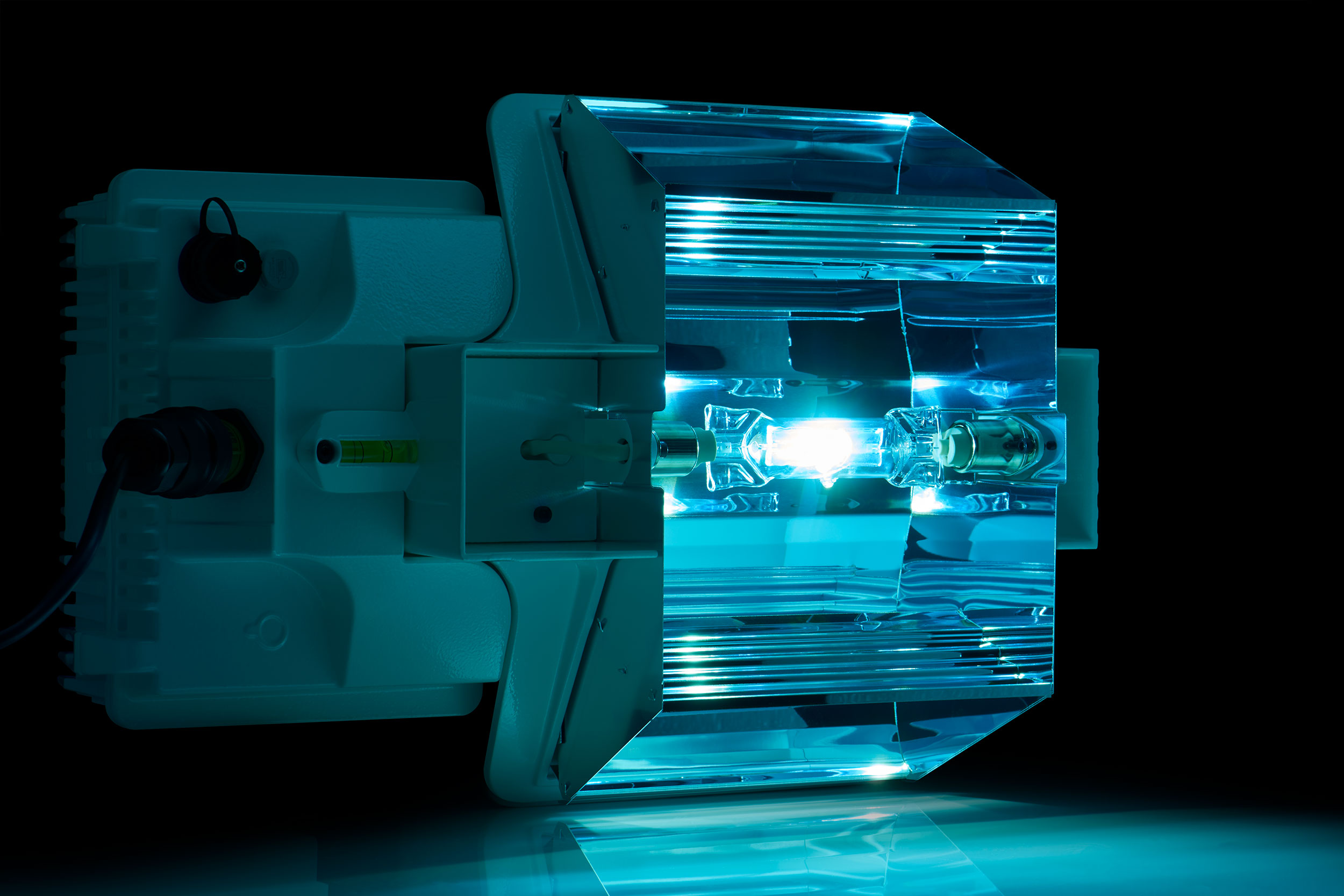

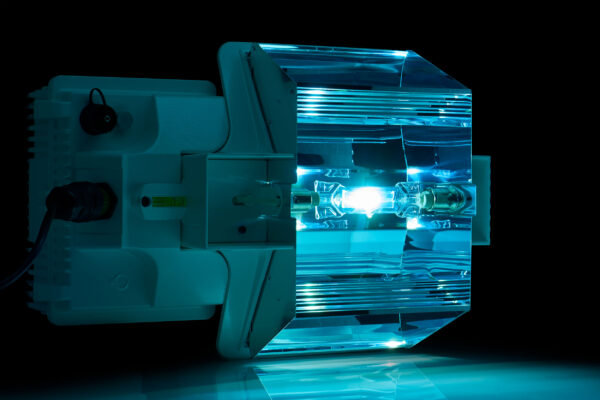

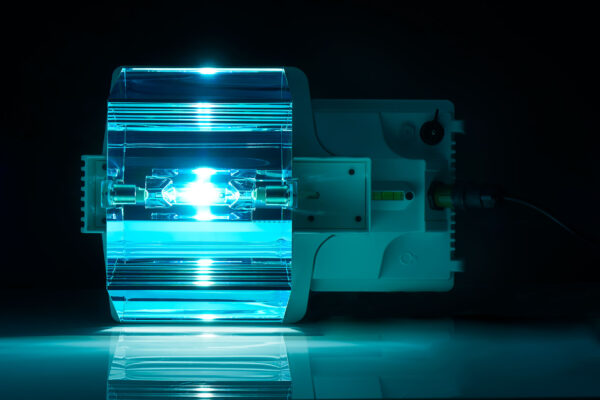

“The DLI UV fixture is the only UV source for plant cultivation that has a broad UV spectrum with all the wavelengths from UV-C (a microscopic amount) to UV-A and a little bit of PAR light. Because of this broad spectrum it works excellently with all the photoreceptors and has a good ratio of UV-A to UV-B.

“The high intensity of the light source lowers the duration the light is required, this is beneficial when trying to minimize pests and molds, as they are more susceptible to higher intensity UV over a short duration than spread out low concentrations. Similar to the sun where UV is most powerful at noon, the DLI UV fixture is recommended to be used for 2-4 hours a day, but variation is of course possible.

“Due to the powerful nature of the UV photon, it can break chemical bonds. This is another function of UV; the breakdown of certain compounds (for instance, some pesticide residues).

“The UV fixture is only 150 watts and covers the area of 4x1000W HPS or equivalent LED fixtures, Since it’s only required to be used for 2-4 hours a day, the addition to 4000W of HPS light is equivalent to only 25-50W over 12 hours.

“The amount of power consumed is minute compared to the effects. The secondary metabolites we watch, increase significantly and terpene profiles resemble what can be found under the sun but now include the other quality aspects gained from cultivating indoors.

“Historically in grow rooms, large air cooled reflectors were used. Top lighting became the predominant way to properly light a crop. Over time this belief has changed and small form factor greenhouse style fixtures are gaining momentum. Increasing efficiency, professionalizing grow rooms and increasing yields.

“While toplighting is a better solution for single layer cultivation, there is nothing wrong with the concept of a multilayer fixture. They should however only be used in true multilayer setups, such as rolling racks with multiple layers of cultivation. Where the distance between the plant and the light needs to be minimized to maximize the effective use of space.

“Multilayer fixtures do not use lenses and have a poor light distribution when looked at from a point of view of a single LED. This is where the form factor comes in, because the LED’s are spread over a large area, the light distribution becomes much better. Toplights generally use lenses to shape the light beam. (A toplight without a lens is trash unless uniformity does not matter to you at all) The DLI APEX LED uses a high quality lens that shapes a broad beam, designed to overlap and provide good uniformity on a large surface area.

“Anyone that is familiar with multilayer cultivation is aware of the challenges when it comes to the climate. With lights mounted at a higher, static, point there is more space for the air below the fixtures to mix and provide a more equal climate. Even though the multilayer fixtures have space between the bars for air to move through they do influence the air, causing turbulent flow. This is another reason to use a toplight in a larger room.

“Toplights provide the ultimate flexibility. Because the fixture does not determine the dimensions of the cultivation area, the grower has a much higher possible range of light levels that can be achieved in a layout. Whether you want a nominal light level of 500μmol/m2/s or 1500μmol/m2/s, it’s all possible. Whereas 500μmol/m2/s with a multilayer fixture may require dimming and 1500μmol/m2/s might not physically fit in the room. It’s this flexibility that will revolutionize the world of grow light as it has done before.

“Products need to fit the application in order to achieve the best results.”