The processes, techniques, and tools used to grow commercial cannabis are constantly evolving. At Cultivation Warehouse we stay on top of all the developments and innovations throughout the industry in order to help our clients maximize their yields, reduce their costs and improve the quality of their crop.

There are numerous options to choose from and the key differences among rack system producers are related to customization, quality & longevity of components, structural integrity, ease of rolling, production lead times, cost and service.

At Cultivation Warehouse we consider all of these factors when recommending a system.

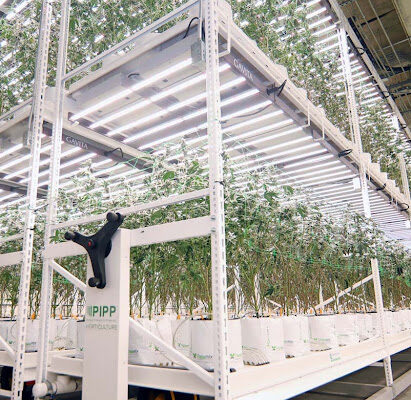

Michigan based Pipp Horticulture shares our commitment to helping cultivators succeed by saving time and money by creating more efficient grow facilities that streamline operations. Over the years Pipp has strategically acquired companies like Greenhaus Industries, Vertical Air Solutions, and GGS Structures to offer turnkey cultivation solutions that increase production and efficiency of grow operations. Pipp recently acquired the assets of Grow Glide to solidify its position as the leading provider of Indoor Commercial Mobile Vertical Grow Racks, Greenhouse Structures, and Air Circulation Systems in North America.

While traditional, single tier horizontal growing has been the industry standard for a while and remains appropriate in specific scenarios, we are seeing more growers moving to vertical grow systems.

Incorporating vertical grow systems into your operation allows you to leverage every inch of your grow room to maximize profits while saving you money on alternative production space expenditures.

The advances in LED lights and the availability of well designed mobile racking systems have given growers the opportunity to maximize their production capability, reduce operating costs, and increase their overall revenue per square foot.

Pipp has become one of the industry-leading providers of Mobile Vertical Growing Solutions with installations in over 2,500 grow rooms worldwide. We’ve enjoyed working with Pipp’s team of in-house professional engineers, CAD designers, and sales support staff on some of the most efficient and profitable grow operations in the world.

Upgrading a single tier facility requires careful planning and a ton of details to consider like

- Floor levelness

- Ceiling height (including ductwork and any other objects hanging)

- Drain locations

- Door locations

- Columns and other obstructions and their potential interference

- Local municipal building codes

- Multi-level access equipment clearance (OSHA-approved ladders or man-lifts)

- Workflow and ergonomics

- Product lead times

- Installation

One of the biggest challenges for growers is ensuring proper airflow through multiple canopies. Dialing in the environment becomes slightly more difficult when you add multiple levels; utilizing sensors throughout each level will help you quickly dial in your VPD. The room is now 3-dimensional, heat rises, and stagnant zones can become serious problems.

Having multiple irrigation zones to tightly control your watering events will allow you to stagger watering to maintain the optimum environment and avoid overwhelming your drains.

Anticipating how increasing your capacity will impact your operations is critical and the teams at Cultivation Warehouse and Pipp can provide you with all of the assistance and expertise for a successful transition.

MORE ABOUT PIPP SYSTEMS:

- Customizable design: PIPP rack systems can be tailored to meet the specific needs of each grower, including size, shape, and number of shelves.

- Durability: PIPP rack systems are built to withstand the harsh environment of a grow room, with sturdy materials and reinforced construction.

- Easy assembly: PIPP rack systems are designed for easy assembly, with a modular design that allows for quick installation and minimal disruption to the growing process.

- Efficient use of space: PIPP rack systems allow for efficient use of space, maximizing yield per square foot and reducing the need for horizontal floor space.

- Flexibility: PIPP rack systems allow for easy movement and flexibility of plants, reducing the risk of damage and allowing for efficient use of labor and resources.

- Support: PIPP offers ongoing support to their customers, including technical assistance, training, and maintenance services.