The Cannabis industry is no stranger to dealing with tough market conditions. In a normal year, cannabis business owners operate without benefits that non-cannabis business owners take for granted: a stable banking relationship; access to ALL standard banking services; standard tax deductions; and the list goes on. As we turn the calendar to 2023, in many of the legacy cannabis markets in the western United States you can add a precipitous decline in cannabis prices to that list, as some of these markets are seeing the wholesale price of a pound drop to under $1,000. This drop in the price of cannabis is leading business owners to dig deep when searching for solutions that will lower Operating Expenses (OpEx). The good news is that many legacy cultivation facilities have one large, low-hanging piece of the proverbial fruit they can pick from the “Reduce OpEx tree:” their HVAC system. The HVAC system makes-up approximately 50% of the energy usage in a cultivation facility, and that can be more than 50% if the HVAC system installed was not a proper fit for the application; many of the legacy facilities fall into the latter category. The Harvest Air Retrofit Unit (HARU) is designed specifically for these legacy facilities. The HARU is designed to supplement your existing system with “free” cooling and dehumidification, thereby extending the lifespan of the existing equipment, while at the same time enjoying the benefit of reduced OpEx that is delivered by using the HarvestWheel – a total energy rotary heat exchanger (i.e., an enthalpy wheel). In many cases, adding a HARU to your HVAC system is minimally invasive and can be installed in between harvests. Lastly, when combined with Harvest Integrated’s “Climate as a Service” offering, you could potentially install a HARU for little or no upfront cost, while at the same time leveraging the experts at Harvest Integrated to operate, maintain, and optimize your HVAC system, letting you focus all your attention on your crops. Let’s dive-in.

Harvest Air & the Harvest Air Retrofit Unit

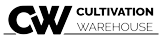

In virtually every HVACD system on the market, compressors are required to do the work of rejecting heat and humidity, therefore it stands to reason that the compressors consume the most energy (by far) in the entire system; approximately 80% of the total system energy is consumed by the compressors. The key to reducing energy consumption is to limit the use of compressors for rejecting heat and humidity. The Harvest Air system leverages the HarvestWheel – a total energy rotary heat exchanger, or an enthalpy wheel – to indirectly use the outside air to cool and dehumidify the space, when the outside air has a lower dew point than the return air from the space; the process works as follows:

For a more comprehensive explanation of the patented Harvest Air system and the HarvestWheel, click on the images below to watch the videos:

When the HarvestWheel is in use, the compressors are either running at partial capacity or they are turned completely off, thereby saving you the energy cost associated with using the compressor(s). When the HarvestWheel is only able to serve a portion of the total heat load, it is necessary to couple the HarvestWheel with a mechanical cooling and dehumidification system to ensure that 100% of the total load is serviced. In a packaged Harvest Air unit, this coupling is integral to the unit itself.

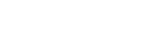

The Harvest Air Retrofit Unit decouples the HarvestWheel from the integrated mechanical cooling system that is downstream of the HarvestWheel in the packaged Harvest Air system. This allows you to couple the HarvestWheel with your existing mechanical cooling units to experience the benefits the HarvestWheel delivers, without a complete changeout of your existing system.

In the case of a retrofit application, a HARU will be installed in series with and upstream from the existing DX RTU’s, as is shown in the image below (concept only; not the exact design that would be deployed).

In this setup, as the outside air dew point drops below the return air dew point, the process will work as follows (follow the numbered steps in the image):

- The HARU will activate and begin pulling return air from the space, while the DX RTU will simultaneously begin closing its return air opening.

- The return air will then pass through the HarvestWheel, where the heat and humidity will be rejected.

- The air will then leave the HARU and be sent to the DX RTU as pre-conditioned air.

- The DX RTU will notice that the air is pre-conditioned and will either use less compressor capacity, or no compressor capacity at all, and will supply the air to the room as usual.

When we model the energy usage in this process for all 8,760 hours in a year, the results for various legacy markets are as follows:

Room Specs

| Room Type: | Flower |

| Room Size: | 1,600 sqft |

| Room Setpoints (temp/RH): | 76F/60% |

| Total Load (sensible + latent): | 44 Tons |

| Sensible Heat Ratio (sensible/total): | .53 |

Definitions

| “Full Economization” | The HarvestWheel handles 100% of the total load |

| “Partial Economization” | The HarvestWheel & the compressors both handle a portion of the total load |

| “100% Mechanical” | The compressors handle 100% of the total load; HarvestWheel is turned off |

Summary of Results

| Location | Energy Reduction vs. Traditional DX | Expected Annual Savings* | 100% Full Economization Hours | Partial Economization Hours | 100% Mechanical Hours |

| Denver | 42% | $15,645 | 2,380 | 5,762 | 618 |

| Spokane | 49% | $15,980 | 2,548 | 6,005 | 207 |

| Seattle | 45% | $13,668 | 1,625 | 6,250 | 885 |

| Portland | 30% | $9,253 | 1,432 | 6,542 | 786 |

| Reno | 45% | $16,590 | 2,434 | 6,136 | 190 |

| Las Vegas | 40% | $13,125 | 2,062 | 5,373 | 1,325 |

| Sacramento | 33% | $10,776 | 547 | 6,070 | 2,143 |

| Santa Maria | 33% | $10,008 | 594 | 7,330 | 836 |

| Desert Hot Springs | 27% | $9,941 | 500 | 4,896 | 3,364 |

*Rate = $.10/kWH

Sample Energy Model Report for Denver, CO

Conclusion

The team at Harvest Integrated understands that the list of headwinds hitting the industry is not shrinking any time soon. This makes it difficult for business owners to find and deploy solutions to reduce their OpEx, even when it’s those very same solutions they need to combat the headwinds. Because of this, our goal with the Harvest Air Retrofit Unit is to deliver a solution that reduces your OpEx AND allows you to pay for that solution with your cash flow, all while being your trusted advisor in delivering your Climate as a Service.

Contact CW to learn more about Harvest Integrated