While the growing process is the foundation for successful cannabis cultivation, the harvesting process is equally essential for determining the quality, potency, and marketability of the final product. Proper timing, handling, trimming, and post-harvest processing are critical for achieving desirable outcomes and meeting the expectations of consumers and regulatory authorities.

Maximizing yields while maintaining product quality directly impacts profitability. A well-organized workflow and efficient space utilization can significantly reduce labor and energy costs.

Jay Larkins, a legacy grower based in Oregon, has spent over two decades experimenting and evolving his harvesting and drying process. The result is the DriFlower HangHarvesting™ System, a unique approach representing significant innovations in harvesting, boosting productivity, providing maximum space efficiency, and improving product quality.

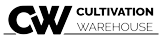

The HangHarvesting approach employs gentle handling and minimal agitation, essential for preserving trichome integrity and potency. Whether in the field or greenhouse, cutting and hanging the plants at the point of harvest when they are the most supple and least prone to breakage or damage keeps the natural oils intact, improves airflow, and prepares your crops for easy transportation to a drying space without subjecting the plants to excessive handling or compression in a tote.

The specially engineered design of DriFlower HangHarvesting™ Systems keeps your dry space clean and organized with minimum loss and maximum efficiency. The plants are only touched once, at the point of harvest, placed on a hanger, and then moved into a climate-controlled environment for curing.

One of the system’s most time-saving benefits is how easily plants can be removed from the hangers once dried in one simple motion. What would otherwise be a labor-intensive process can now be accomplished in seconds with DriFlower.

The heart of every HangHarvesting System is the DriFlower hanger. The most popular is the 41″ J-Hanger, a rigid and durable two-piece, dual riveted aluminum hanger with a built-in handle for easy transport and organizing, a precision stick-slot with a raised center for accurate balancing with raised ridges and end tips to keep plants secure and in place. J-Hangers are available in 21″, 31″ and 41″ lengths to allow for convenient moving and monitoring no matter the dry room size. When combined with the other DriFlower components – Sticks, Dri-Posts, and Brackets – the system can be easily assembled for various applications or custom-configured for use in trucks, other transport, or unique drying spaces.

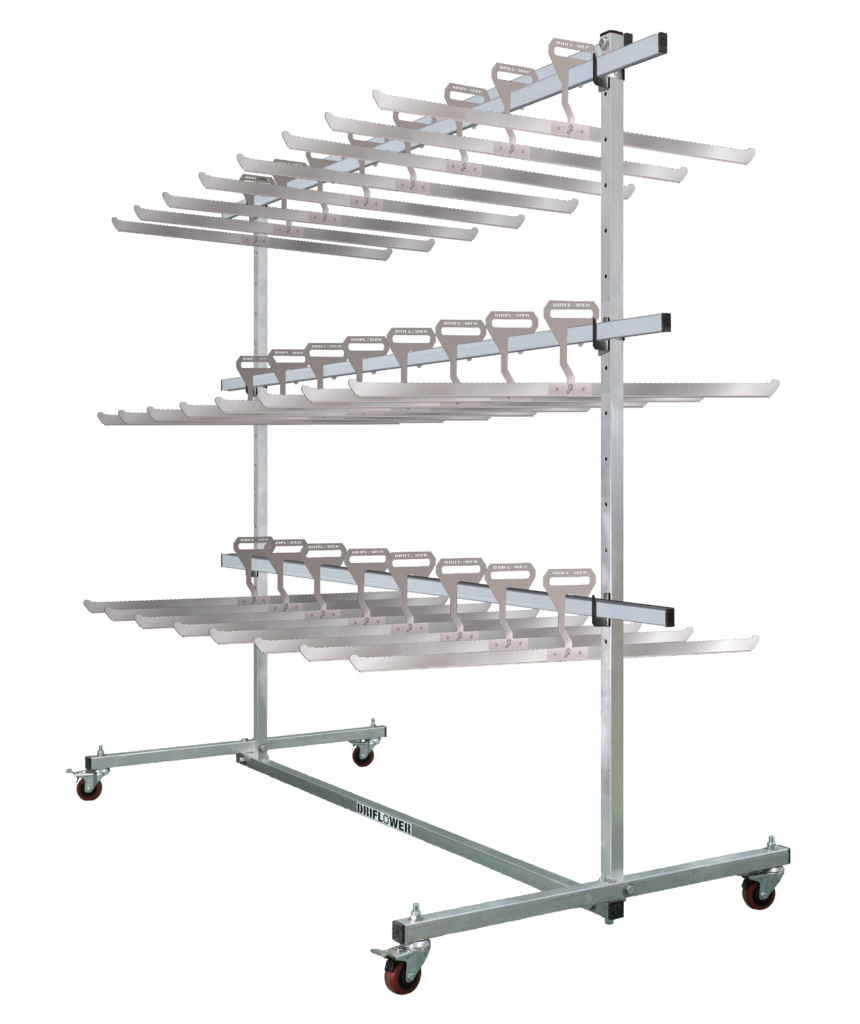

DriFlower offers a variety of ready-to-ship solutions, from lightweight rolling racks to heavy-duty, forkliftable, stackable racks ideal for large-scale use in transport and warehouses.

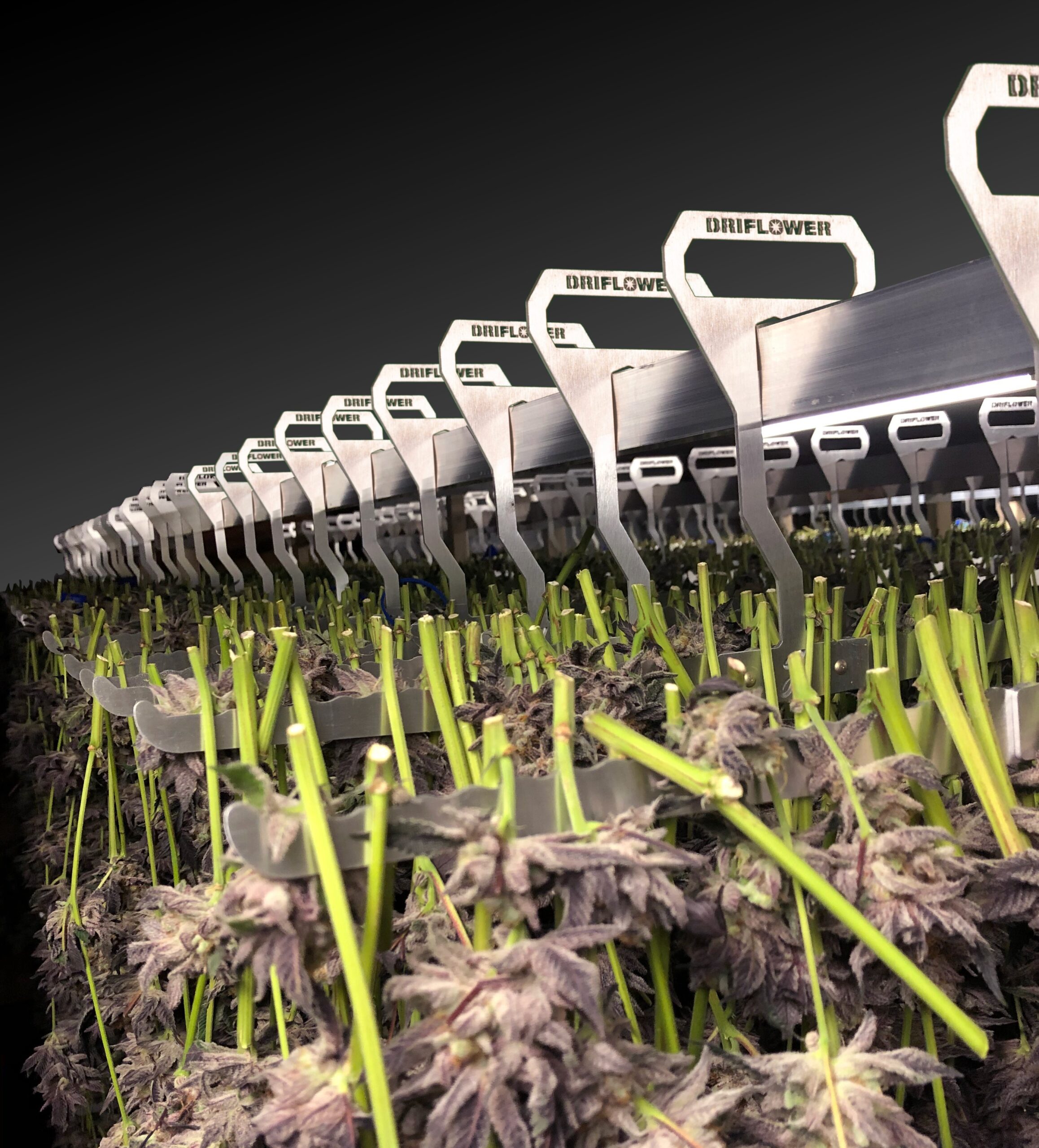

The DriFlower™ Lil’ Buddy Personal Rolling Harvest-Rack is small enough to roll through a standard doorway while holding four hangers loaded with fresh cut flower (approximately 40-50 wet pounds). This heavy-duty, all-metal rolling Harvest-Rack with locking castors and safety rubber bumpers is the smallest Harvest-Rack option and accelerates transferring crops from the grow room to the dry room.

The DriFlower™ Rolling Dri-Rack is a mobile dry room solution that can hold 24 J-hangers across three tiers. It provides a drying rack that manages approximately 240 wet pounds (24 lbs dried/trimmed) in a 42″x 91″ footprint.

The DriFlower™ PRO PODS are the clear choice for trucking and storing large quantities of hemp or cannabis. These heavy-duty drying racks are ideal for use in warehouses and processing facilities.

Each PRO POD has 4 (collapsible) vertical posts with integrated stick slots to accommodate either three tiers (6 sticks / 48 hangers) or four tiers (8 sticks / 64 hangers) of HangHarvesting potential, and they can stack three high to provide 24 vertical feet of hanging space on an 8’x8′ footprint.

Once the fully loaded sticks have been secured in the PRO PODs’ stick slots, each PRO POD can be lifted via forklift, placed on a transport vehicle, and moved to the drying facility, significantly reducing the labor required at several points.

DriFlower HangHarvesting systems are highly scalable and can meet your growing needs. Whether you choose a conversion kit, a rolling Dri-Rack, or a customized build-out for your dry room, you can optimize the workflow, minimize labor costs, and maximize your drying space, resulting in a more productive and profitable harvest.

If you’re looking to streamline the harvest and drying process, minimize crop handling, simplify transport, easily organize your dry space with one-touch hanging, maximize airflow during drying, keep your product organized and sanitary, and unload your hangers in a fraction of the time you should consider DriFlower.